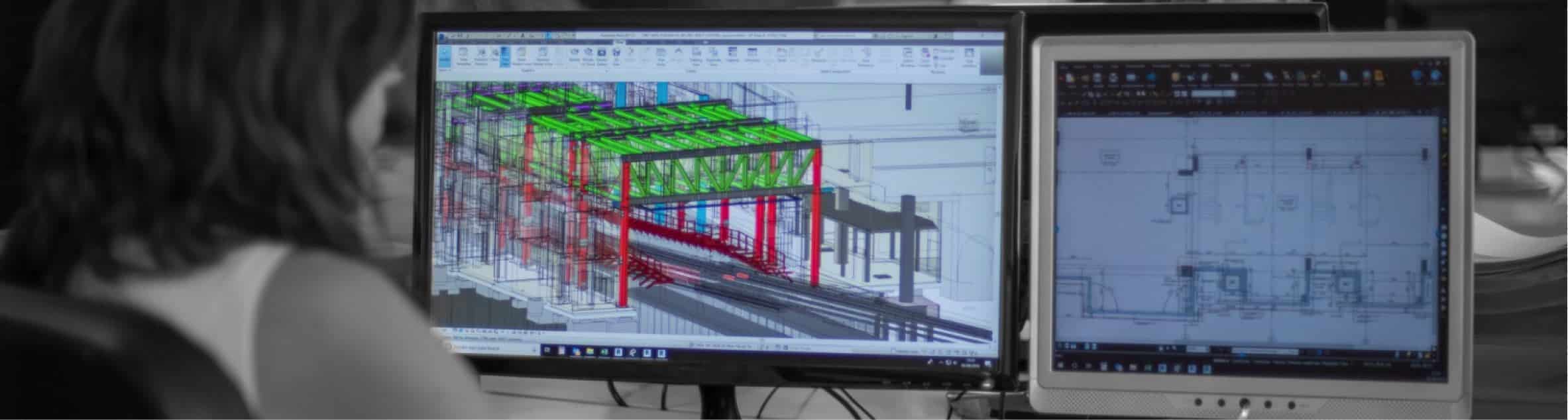

MV-BIM have been many years integrating BIM to technical design and manufacturing process. By virtually constructing the building we can control this process ensuring that maximum level of accuracy and quality is achieved in the projects we are involved.

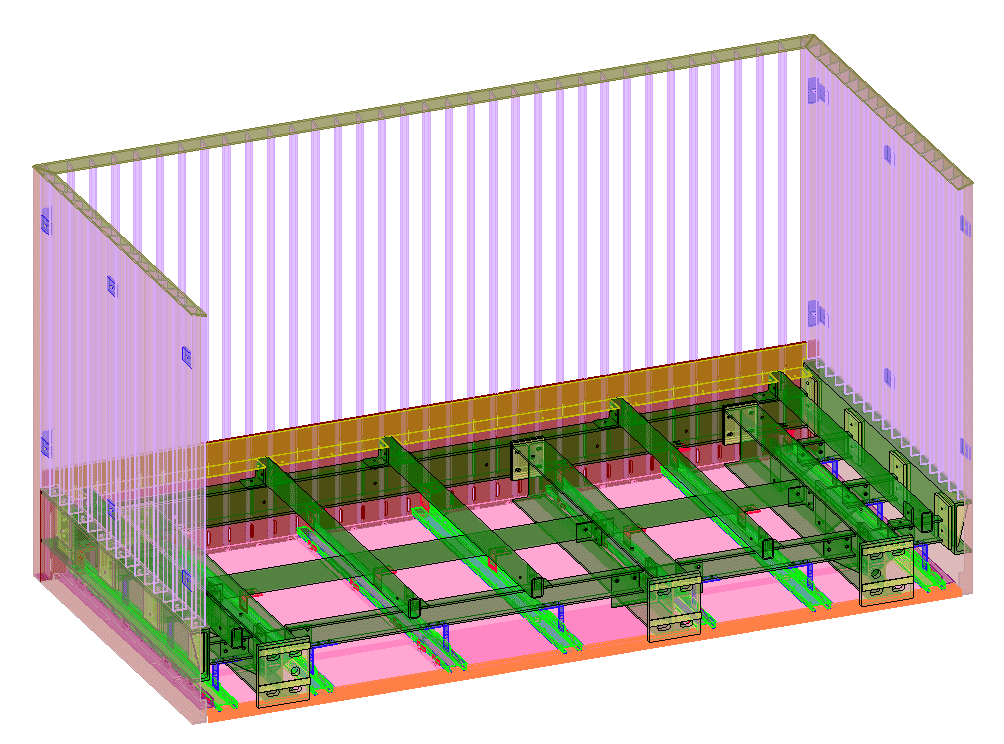

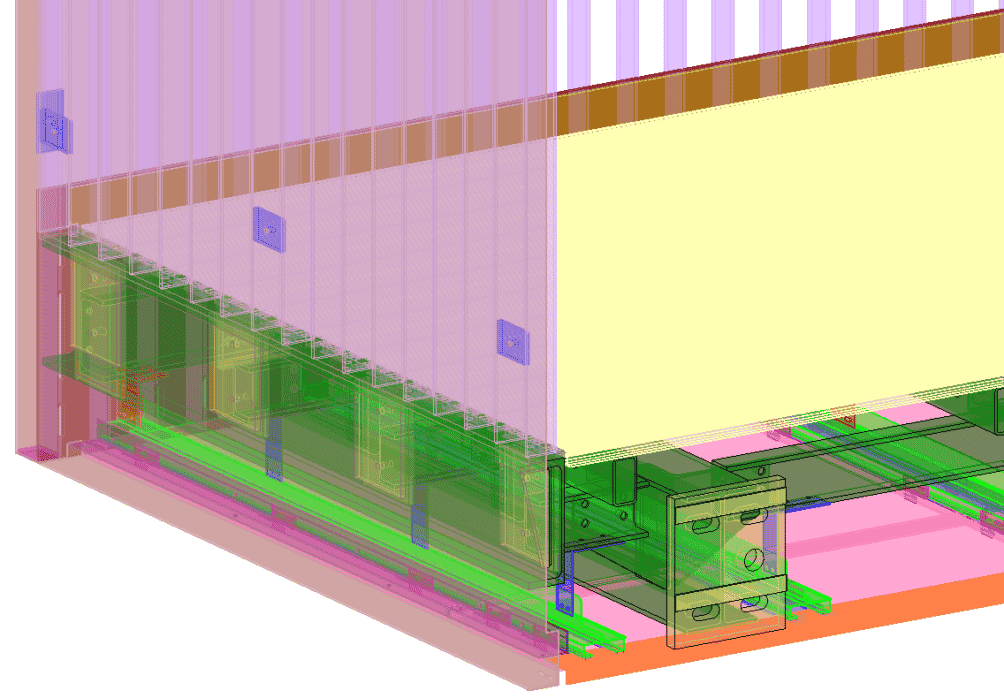

We produce BIM models with a very high level of definition in terms of geometry and information. We convert these LOD 400 models into a comprehensive and fully itemised package of graphical assembly instructions for external envelope elements that can be prefabricated offsite by the contractor. From panels and fixings to any substructure components of multiple construction systems of the building, like balustrades, façade, ceilings, windows, curtain walls, flashings, copings, etc. Individual elements can be codified and labelled in the workshop. Then on site, documentation minimises error, eliminates waste and facilitates the most rapid and safe installation.

Interoperability and seamless workflows from Design to Fabrication are critical, and choosing the right and most sophisticated applications is fundamental. We have developed strong skills not only with Revit but other specialized 3D softwares like Advance Steel and Inventor which offer more advanced model design capabilities for designers and engineers which make parts and assembly modelling more precise and intuitive, while reducing repetitive tasks.

We have developed SFS panels design, pre-fabrication and assembly process, as we have connected our BIM model to the fabrication machine directly. We can export CNC codes that contains geometrical information about each individual stud of every SFS panel, for the machine to fold, cut and codify the studs accordingly to be assembled in factory and transported and installed on site.

Codified installation drawings exported from LOD 400 model allows site teams to install in a very efficient manner, reducing risk improving health and safety on-site. These are also used as a communication tool between design and site teams, helping them understand between each other, resolve and construct some key parts of the building efficiently.

We understand the role that BIM can play for site design and installation process. And we find fascinating the exercise of our design work, preparing the technical design, fabrication and assembly drawings with the combination of the digital technology, global supply chains and automated offsite-manufacturing. We consider DfMA as part of our BIM processes, examinating innovative ways of using digital tools to transition more effectively from design to construction and adopt more collaborative ways of working.